NDT Tests on Concrete

NDT stands for Non-Destructive Testing and these tests carry out in so many different fields like construction, pressure vessels, boilers, aircraft, trains, pipelines, and etc. And this post will outline NDT Tests on concrete. These tests carry out assuring the current state without doing any damage to the test specimen (building, component, or materials). There is a wide range of tests under this. For example, the following are some NDT Tests on concrete and several features test by NDT tests. Another important fact about the NDT test is that it is possible to execute these tests at any stage of the life cycle of infrastructure.

NDT tests carry out to test the following.

- Estimating the in-situ compressive strength

- Estimating the uniformity and homogeneity

- Estimating the quality in relation to the standard requirement

- Identifying areas of lower integrity in comparison to other parts

- Detection of the presence of cracks, voids, and other imperfections

- Monitoring changes in the structure of the concrete which may occur with time

- Identification of reinforcement profile and measurement of cover, bar diameter, etc.

- Condition of prestressing/reinforcement steel with respect to corrosion

- Chloride, Sulphate, alkali contents, or degree of carbonation

- Measurement of Elastic Modulus

- Condition of grouting in prestressing cable ducts

Following are some examples of NDT tests

- Rebound Hammer Method

- Concrete Carbonation Test

- Ultrasonic Pulse Velocity Method

- Radio Active Methods

- Penetration Method

NDT test on concretes mainly refers to the compression strength and other properties of the concrete such as corrosion in concrete, permeability, voids in concrete to determine the durability of concrete.

When it comes to the maintenance of any structure, NDT tests are very important to assure the integrity to avoid disastrous accidents. These are very profitable tests as this saves both money and time. And it is very important to select the ideal type of test for the specimen.

1. Rebound Hammer Method

Rebound hammer or Schmidt hammer is used to determine the compressive strength of concrete and this is also used to get an idea about the reinforcement cover of the concrete.

In this test, the plunger of the hammer press against the specimen to be tested perpendicularly, and the surface should be free from dirt. Then this rebounds and this rebound depends on the hardness of the concrete specimen which is a result of the quality of cement, aggregates, moisture content and etc. With this rebound value, the compressive strength of the test specimen can be calculated directly through the graph given in the rebound hammer taking this rebound value as the rebound index or rebound number. Weak concrete surfaces indicate low rebound values. It also should be noted that if the test specimen is not homogeneous rebound number will not be accurate and the accuracy of this test is -+25%.

2. Concrete Carbonation Test

Carbonation is the process where CO2 in the atmosphere reacts with the calcium oxide in concrete to form calcium carbonate.

This test carries out with a chemical indicator. The most commonly used indicator is a solution of phenolphthalein in alcohol or water. When phenolphthalein solution applied to fresh strongly alkaline concrete, it turns pink and the phenolphthalein indicator remains colorless if the specimen has carbonated. It’s essential to carry out applying a phenolphthalein solution to a freshly exposed specimen.

Concrete is alkaline in nature having a pH of more than 12.6. That is why covering concrete is so important to protect the reinforcement from corrosion due to this alkaline nature of concrete. Once reinforcement corroded, that forms a thin layer over reinforcement bars which leads to an increment of volume. This results in cracks in concrete. These cracks further expose the concrete to CO2 thereby cause the structure to destruct. This is a very simple test.

3. Ultrasonic Pulse Velocity Method

This test carries out to check the quality of concrete and natural rocks. In this test, the strength and quality of concrete or rock are assessed by measuring the velocity of an ultrasonic pulse passing through a concrete structure or natural rock formation.

This test is conducted by passing a pulse of ultrasonic through concrete to be tested and measuring the time taken by the pulse to get through the structure. Higher velocities indicate good quality and continuity of the material, while slower velocities may indicate concrete with many cracks or voids.

Ultrasonic testing equipment includes a pulse generation circuit, consisting of an electronic circuit for generating pulses and a transducer for transforming electronic pulse into a mechanical pulse having an oscillation frequency in the range of 40 kHz to 50 kHz, and a pulse reception circuit that receives the signal.

The transducer, clock, oscillation circuit, and power source are assembled for use. After calibration to a standard sample of the material with known properties, the transducers are placed on opposite sides of the material. Pulse velocity is measured by a simple formula.

4. Radio Active Methods

These include the X-ray and Gamma-ray penetration tests for measurement of density, thickness, amount of water in concrete, location of reinforcement, to test whether honeycombs has occurred and etc. Also, the neutron scattering and neutron activation methods are used for moisture and cement content determination. Gamma radiography is increasingly accepted in England and Europe.

This method is simple and running costs are small, although the initial installation price is high.

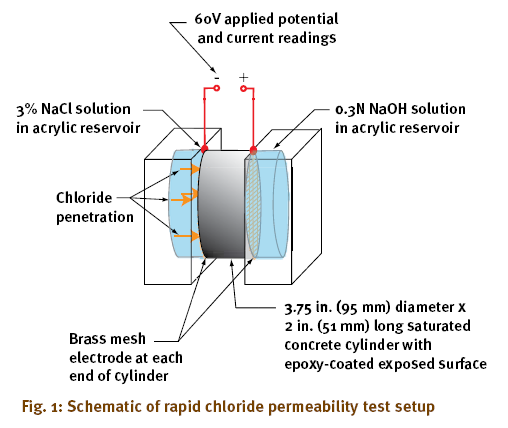

5. Rapid Chloride Permeability Test

The main ways in which chloride ions penetrate concrete are through hydrostatic pressure, capillary action, and diffusion. The least common method of chloride ion penetration is through hydrostatic pressure which occurs when water, containing chloride ions, is drawn into the concrete from differing pressures inside versus outside of the concrete. A constant hydraulic head such as this is very unlikely on actual concrete structures such as bridge decks, so it is usually of little concern. However, this mechanism could represent a major concern in marine environments. Another, more common, form of chloride attack in concrete is from capillary action. Concrete contains small void spaces that are referred to as capillaries which are essential to the ability of concrete to safely expand and contract during periods of freezing and thawing. However, during cycles of wetting and drying, water containing ions such as chloride can be drawn into these capillaries. When concrete becomes wet, surface tension forces draw water, containing chloride, into these capillary void spaces. Over the life span of the concrete, there is a net flow of water and ions into the concrete which can become a problem.

This test does not actually directly measure chloride ion penetration, but rather the electrical conductance of concrete. Conductivity is the measure of the ability to conduct electrical current. So, the test measures the ability of concrete to conduct electrical current, an ability that has been proven to be correlated to chloride ion penetration. The test consists of a conditioning phase and a testing phase.

Posted on 2021/01/16 11:34 AM